Scouring Loss in Cotton Material

SCOPE

This SOPs prescribes a method for determining the scouring loss in grey and finished cotton textiles materials.

PRINCIPLE

The test specimen is taken and its moisture content is determined. Another test specimen is scoured, washed and its oven-dry mass is determined. The scouring loss is calculated on the basis of oven-dry mass of the test specimen.

APPARATUS

- Soxhlet apparatus

- Desiccator

- Weighing balance – accurate to 0.001g

- Oven – 105° ± 3°C

- Beaker 250 ml

REAGENTS

- Desizing enzyme – Diastase.

- Sodium chloride

- Caustic Soda solution – 2 percent added with 1% Turkey red oil.

- Acetic acid – 1 percent

- Chloroform

PROCEDURE

A. Determination of moisture content:-

- Weigh accurately 3.0 g of test specimen in a clean dry and tarred weighing bottle.

- Place the weighing bottle with test specimen in the drying oven maintained at 105° ± 3°C for 2 hours.

- Cool the specimen in a Desiccator and weigh accurately the oven dry weight of specimen.

- Repeat the process of heating, cooling and weighing until constant mass is achieved.

Calculate the percentage of moisture in the test specimen, by the following formula:

Moisture content, percent (m) = (a-b) x 100 / a

Where,

a = original mass, in g of the test specimen, and

b = oven-dry mass, in g of the test specimen.

Determination of scouring loss by severe method

- From the sample, cut two test specimens each weighing about 5 g, as M1.

- If the sample under test is yarn, cut each test specimen, separately into pieces about 15 cm long, form into separate bundle and tie each bundle loosely round the middle. If the sample under test is fabric, trim each test specimen parallel to the directions of warp and weft and pull out, to form a fringe, 5 threads all rounds.

- Dip the specimen in a 100 ml solution of 5g diastase and 10g of sodium chloride, at temperature 50°C.

Note: – pH of diastase and sodium chloride solution should be between 6.5 to 7.7.

- Allow the specimen to remain in solution for 11/2 hours.

- During this period, take the specimen from desizing bath and wring it by hand in every 20 minutes. Replace the sample after wringing.

- At the end of period, remove the specimen and wash it thoroughly without wringing with 50 ml of hot water.

- Then wash the specimen with 50 ml of cold water. Repeat the process of washing with hot and cold water successively for four times.

- After washing, put the specimen in 100 ml of caustic soda solution in a conical flask and boil for one hour.

Note: – add adequate quantity of water to make to make up for loss during boiling.

- At the end of one hour, remove the specimen and wash it thoroughly without wringing in hot water.

- Now dip the specimen in 1 percent acetic acid solution for 5 minutes.

- Finally wash the specimen without wringing with cold water.

- Dry the specimen with weighing bottle in an oven at 105°C for 2 hours.

- Remove from oven, cool in Desiccator and weigh accurately

1Repeat the procedure of drying, cooling and weighing until a constant mass is achieved. Note as M2.

Determination of scouring loss by Mild method

- Weigh about 5 g of test specimen accurately and form into separate bundle and tie bundle loosely round the middle. M1

- Extract the specimen for one hour with chloroform in a Soxhlet apparatus at the rate of 6 cycles per hour.

- Remove the specimen from Soxhlet and dry chloroform in the air for 45 minutes.

- Wash the specimen with hot running water and wringing by hand. Repeat the process of washing with hot water and wringing by hand 12 times in succession.

- Immerse the specimen in 125 ml of 0.5 % diastase solution at 50°C for 15 minutes.

- Wring by hand three times in succession, return the specimen into solution and heat to 70°C.

- Allow the specimen to remain in solution for 15 minutes and then wash it with hot running water.

- Squeeze and dry the specimen at 105°C in an oven for 1-2 hours.

- Remove from oven, cool in Desiccator and weigh accurately

- Repeat the procedure of drying, cooling and weighing until a constant mass is achieved. Note as M2.

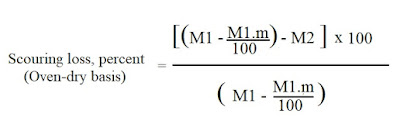

CALCULATION

Calculate the percentage of scouring loss by the following formula:-

Where

M1 = original mass in g of sample

m = moisture content, percent; and

M2 = oven-dry mass in g of the sample after treatment

REFERANCE: – IS 1383:1977- Method for determination of scouring loss in grey and finished textiles materials.