Colour Fastness of Perspiration

APPARATUS

- Perspirometer

TOOLS/ACCESSORIES

- Stainless-mass 5 Kg

- Acrylic resin plate base-11.5X6 cm and

- Thickness 0.15cm

- Oven temperature (37±22°C)

- Two adjacent fabrics or multi fabrics (each 10X4 cm)

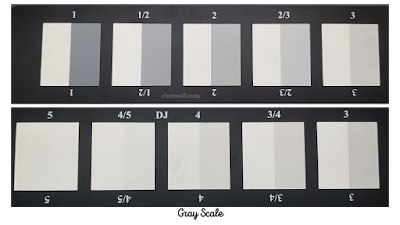

- Grey scale.

REAGENTS

Alkaline solution:

- 0.5g of 1-histidine monohydrochloride Monohydrate + 5 g of NaCl + 5 g of Na2 HPO4.12H2O in 1000ml distilled water. PH-8 (adjust with 0.1N NaOH ).

Acid solution:

- 0.5g of 1-histidine monohydrochloride Monohydrate + 5 g of NaCl + 5 g of Na2 H2PO4.2H2O in 1000ml distilled water. PH-5.5 (adjust with 0.1N CH3COOH ).

NO. OF SAMPLE

More than one

Note: If sample is multicolor fabrics- minimum one sample for each colour

NO. OF TEST PERFORMED

4 (2 for Alkaline solution &2 for Acid solution)

PEOCEDURE

- Condition the sample to moisture equilibrium in standard atmosphere temperature 27±22°C and HR 65± 2 %.for 24 hour.

- Wet the sample thoroughly in alkaline solution at liquor ratio (50:1).

- Allow it to remain in the solution at room temperature for 30 min.

- Press and move it time to time to ensure good and uniform penetration of the liquor.

- Pour of the solution and wipe the excess liquor off the sample between two glass rods.

- Then place the composite specimen between two acrylic resin plates (11.5X6cm) under pressure 12.5K pa.

- Keep testing device in oven for 4 hour at 37± 22°C.

- Open out the composite specimen by breaking the stitching on all side except one of the shorter side.

- Dry by hanging it in air (not exceeding 602°C.)

- Treat the second composite specimen similarly as in follow above procedure using acidic solution instead of alkaline solution.

- Repeat the test with other composite specimens taken from the other test pieces.

- Evaluate the change in colure of the treated test specimen by the method prescribed in IS 789-1982.

- The degree of staining of the two pieces of adjacent fabrics by the method in IS 769-1982

REFFERENCE SPECIFICATION : IS 971-1983