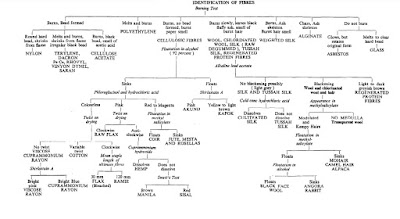

Fiber Analysis: Qualitative

1. Grouped By Generic Classifications of Textile Fibres

Group 1 – Natural Fibers

|

Natural Fibers

|

|

|

a.

Cellulose (Vegetable)

|

b.

Keratin (Animal)

(Natural

Protein Fibres)

|

c.

Mineral

|

|

|

1.

Seed Fibres

Cotton

Akund

Kapok

|

1.

Wool & Chlorinated wool

|

·

Asbestos

|

|

|

2.

Silk

Bombyx

(cultivated)

Tasar

or Tussah (wild)

|

|

|

2.

Bast Fibres

I. Low Lignin Content

Linen or Flax

Ramie

II. High Lignin Content

Jute

Mesta

Rosella

True Hemp

Sunn Hemp

|

|

|

3.

Alpaca

Camel

Cashmere

Horse

llama

Mohair

Rabbit

Vicuna

Yak

|

|

|

3.

Leaf Fibres

Manila

Hemp (Abaca)

Sisal

(Agave)

|

|

|

4.

Fruit or Nut Fibre

Coir

|

|

Group 2 – Man-Made Fibers

|

Man Made Fibers

|

|

|

a.

Regenerated Fibres

|

b.

Synthetic Fibres

|

|

|

1.

Cellulosic

Viscose

Cuprammonium

Acetate

(secondary & triacetate)

Polynosic

High-Wet

Modulus Fibres (HWM)

|

1.

Polyamides

Nylon

6

Nylon

66

Nylon

610

Etc…

|

|

|

2.

Polyester

Terylene

Terene

Dacron

Etc…

|

|

|

2.

Protein

Casein

Groundnut

Fibre

Zein

|

|

|

3.

Polyvinyl Derivatives

I.

Polyvinyl

Chloride

Pe Ce

Rhovyl

Etc…

II.

Polyvinyl

Chloride Acetate

Vinylon

ST

Vinyon

HH

III.

Polyvinyl Chloride Acrylonitrile

Vinyon

N

Dynel

IV.

Polyvinylonitrile (Acrylic fibre)

Orlon

Acrilan

V.

Polyvinyl

Alcohol

Vinylon

Kuralon

VI.

Polystyrene

& Copolymers

Styroflex

Polyfil

Etc..

VII.

Polyvinylidene Chloride & Copolymers

Saran

Velon

|

|

|

4.

Polyolefins

I.

Polyethylene

Polythene

II.

Polypropylene

Reevon

|

|

Group 3 – Inorganic Fibers

Inorganic Fibres

a. Glass

b. Metal

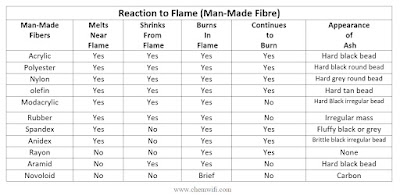

2. Fibre identification by Burning Test-

A small tuft of fibres is held by forceps in the frame of a micro-burner for about

10 seconds and is then removed. It is noted whether the tuft burns or not; whether it forms any bead or whether the ash skeleton is retained; the type of smell emitted during burning is also noted. The test is carried out in daylight.

Reaction to Flame

3. Fibre identification by Density

Identification Density & Melting

Point

|

Natural Fibre

|

Density g/cc

|

Melting Point ℃

|

Asbestos (chrysotile)

|

2.1-2.8

|

Over 350

|

Cellulose

|

1.51

|

none

|

Silk

|

1.32-1.34

|

none

|

Wool & Other Hair

|

1.15-1.30

|

none

|

Identification Density & Melting

Point

|

Man-Made Fibre

|

Density g/cc

|

Melting Point ℃

|

Acetate, Secondary

|

1.32

|

260

|

Acetate, tri

|

1.30

|

288

|

Acrylic

|

1.12-1.19

|

none

|

Anidex

|

1.22

|

Softens at 190℃

|

Aramid

|

1.38

|

Char at 400℃

|

Azlon

|

1.30

|

none

|

Modacrylic

|

1.30 or 1.36

|

188 or 120

|

Novoloid

|

1.25

|

none

|

Nylon

|

1.12-1.15

|

213-225

|

Nylon 6,6

|

1.12-1.15

|

256-265

|

Nytril

|

1.20

|

218

|

Polyester

|

1.38 or 1.23

|

250-260 or 282

|

Polyethylene

|

0.90-0.92

|

135

|

polypropylene

|

0.90-0.92

|

170

|

Rayon

|

1.51

|

none

|

Rubber

|

0.96-1.06

|

none

|

Saran

|

1.70

|

168

|

Spandex

|

1.20-1.21

|

230

|

Vinal

|

1.26-1.30

|

–

|

Vinyon

|

1.34-1.37

|

230 or 400

|

Identification Density & Melting

Point

|

Inorganic Fibre

|

Density g/cc

|

Melting Point ℃

|

Metallic

|

Varies

|

Over 300

|

Glass

|

2.4-2.6

|

850

|

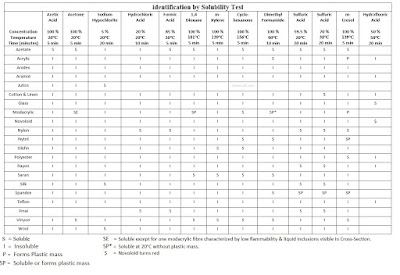

4. Fibre identification by Solubility Test

Floatation Test –

A small sample of the fibre after degreasing in benzene-methanol mixture ( 3:2 ) is placed in the test liquid and pushed below the surface by means of a glass rod. The liquid should be illuminated transversely and viewed against a black background to observe whether the sample floats on the surface or sinks.

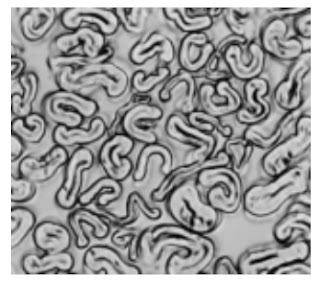

5. Fibre identification by Microscope

Microscopic Analysis

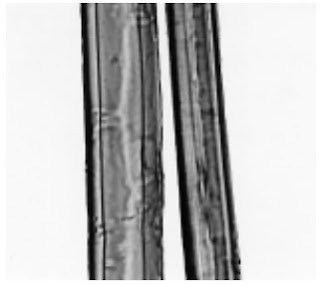

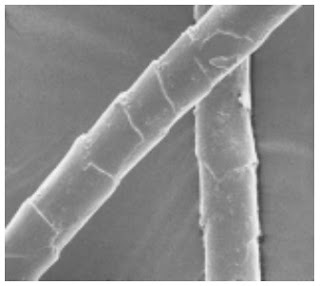

Longitudinal Examination – Place a small number of fibres on a glass slide in a suitable

mounting medium, cover the fibres with a covering glass. Examine the fibres at a specified magnification under microscope.

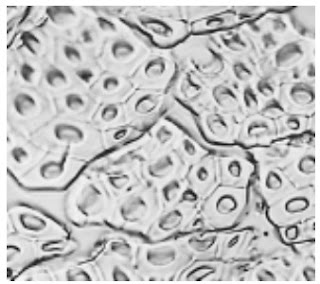

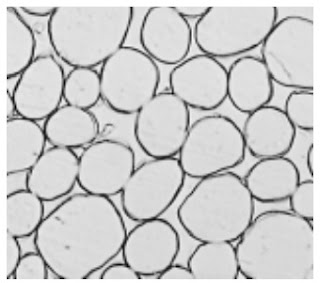

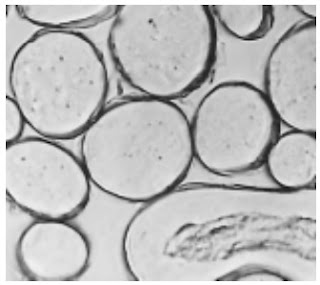

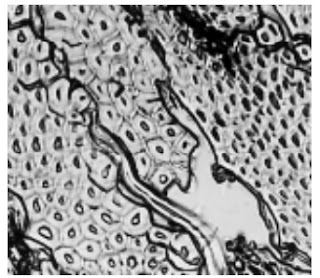

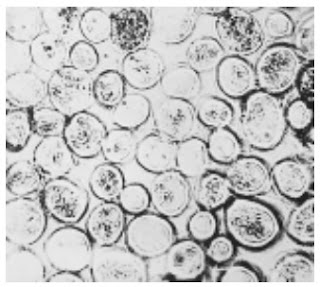

Cross-Section Examination – Take a tuft of fibres and prepare the specimen with the

cross-sectioning device, place it on a glass slide in a suitable mounting medium and cover it with a covering glass. Examine the fibres at a specified magnification under microscope.

Photomicrographs of Common Textile Fibers

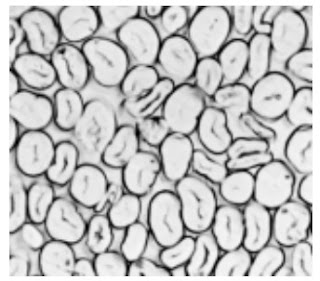

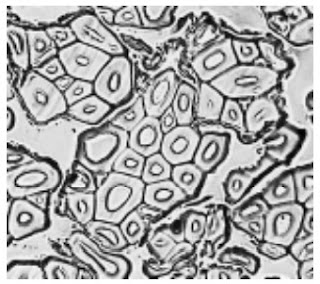

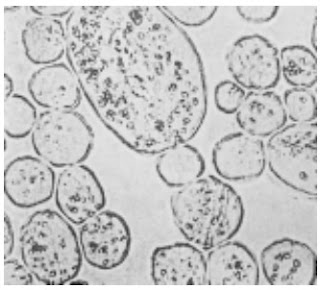

Cross-Section 500X – Cotton fibre (not mercerized)

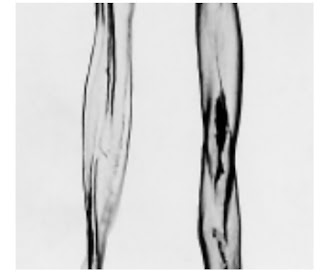

Longitudinal View-500X – Cotton fibre (not mercerized)

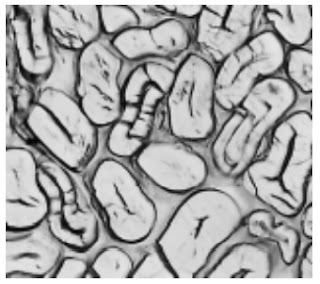

Cross-Section 500X – Cotton fibre (mercerized)

Longitudinal View-500X – Cotton fibre (mercerized)

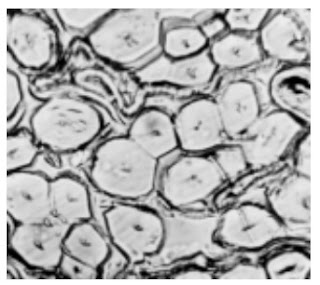

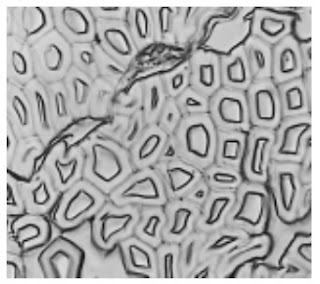

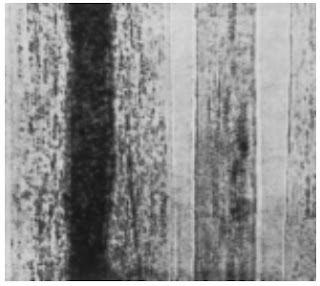

Cross-Section-500X Flax fibre

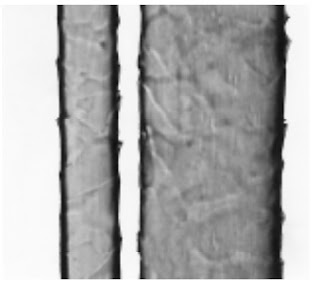

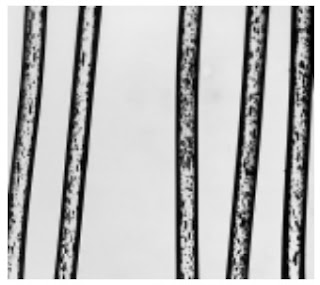

Longitudinal-View-500X-Flax fibre

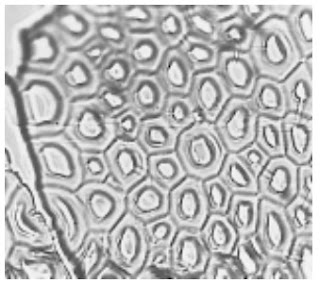

Cross-Section-500X- Hemp fibre

Longitudinal-View-500X-Hemp fibre

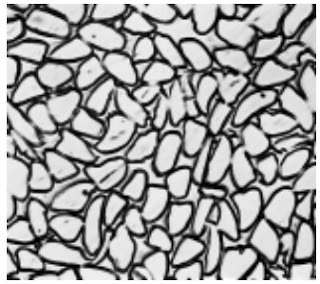

Cross-Section-500X- Jute fibre

Longitudinal-View-500X-jute-fibre

Cross-Section-500X-Ramie fibre

Longitudinal-View-500X-Ramie fibre

Cross-Section-500X- Sisal fibre

Longitudinal-View-500X-Sisal fibre

Cross-Section-500X-Abaca fibre

Longitudinal-View-500X-Abaca fibre

Cross-Section-500X-Kenaf-fibre

Longitudinal-View-500X-Kenaf-fibre

Cross-Section-500X-Wool-fibre

Longitudinal-View-500X-Wool fibre

Cross-Section-500X-Mohair fibre

Longitudinal-View-500X-Mohair-fibre

Cross-Section-500X-Phormium-fibre

Longitudinal-View-500X- Phormium fibre

Cross-Section-500X- Cashmere fibre

Longitudinal-View-240X- Cashmere fibre

Longitudinal-View-1500X- Cashmere fibre

Cross-Section-500X-Camel hair

Longitudinal-View-500X-Camel-hair-fibre

Cross-Section-500X-Silk-fibre

Longitudinal-View-500X-silk-fibre

Cross-Section-500X-Silk-tussah-fibre

Longitudinal-View-500X-silk-tussah-fibre

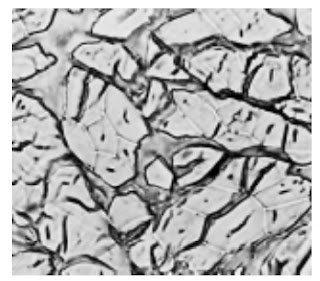

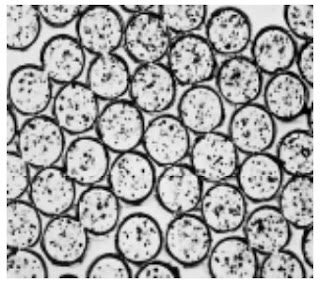

Cross-Section-500X- Polyester fibre

Longitudinal-View-250X-Polyester-fibre

REFFERENCE SPECIFICATION : IS 667: 1981 & AATCC 20- 2007